INTERNATIONAL CONNECTIONS

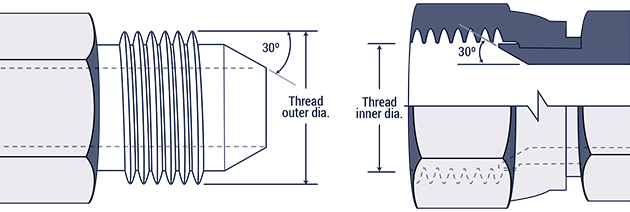

British Standard Pipe

British Standard Pipe connections come in two different types: British Standard Pipe Parallel (BSPP); and British Standard Pipe Tapered (BSPT).

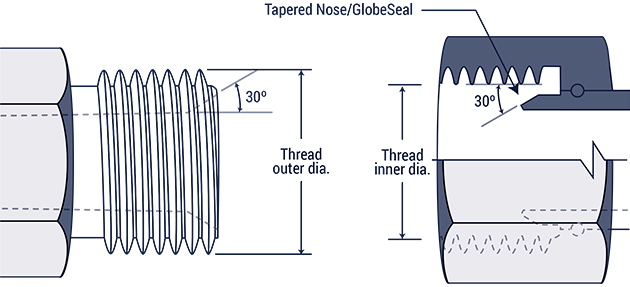

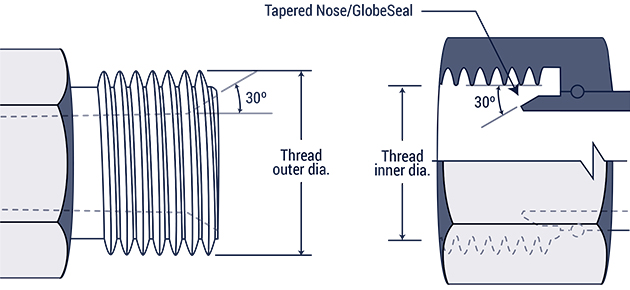

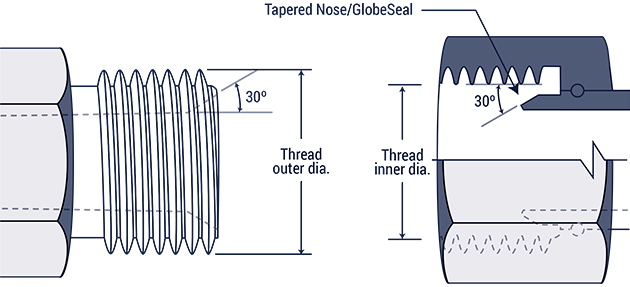

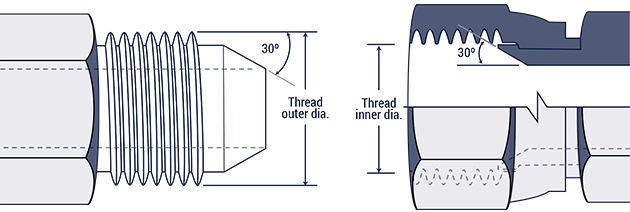

British Standard Pipe Parallel (BSPP) :

This connection has a male half with a 300 seat, and a female half with a rotating tapered nose, that forms the seal.

NOTE: The male connector may appear to look like the male American National Pipe Straight Mechanical, or NPSM; however, their thread pitches are not the same, and are not compatible.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

1/8 - 28

|

3/8

|

0.38

|

11/32

|

0.35

|

|

1/4

|

-4

|

1/4 - 19

|

33/64

|

0.52

|

15/32

|

0.47

|

|

3/8

|

-6

|

3/8 - 19

|

21/32

|

0.65

|

19/32

|

0.60

|

|

1/2

|

-8

|

1/2 - 14

|

13/16

|

0.82

|

3/4

|

0.75

|

|

5/8

|

-10

|

5/8 - 14

|

7/8

|

0.88

|

13/16

|

0.80

|

|

3/4

|

-12

|

3/4 - 14

|

1

1/32

|

1.04

|

31/32

|

0.97

|

|

1

|

-16

|

1 - 11

|

1

5/16

|

1.30

|

1

7/32

|

1.22

|

|

1

1/4

|

-20

|

1

1/4 - 11

|

1

21/32

|

1.65

|

1

9/16

|

1.56

|

|

1

1/2

|

-24

|

1

1/2 - 11

|

1

7/8

|

1.88

|

1

25/32

|

1.79

|

|

2

|

-32

|

2 - 11

|

2

11/32

|

2.35

|

2

1/4

|

2.26

|

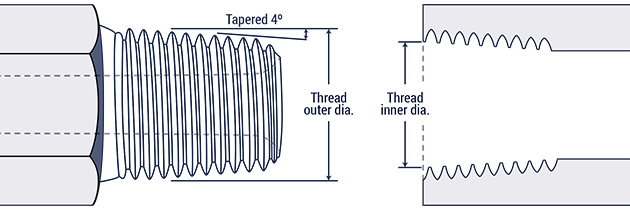

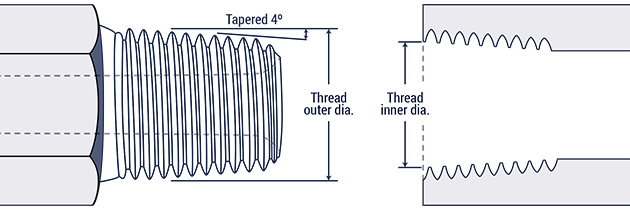

British Standard Pipe Tapered (BSPT) :

These are connectors where the seal is made between a tapered male and female thread.

NOTE: Although the BSPT male connector appears to look like the National Pipe Tapered Fuel, or NPTF; their thread size and form are not the same and therefore they are not compatible.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

1/8 - 28

|

3/8

|

0.38

|

11/32

|

0.35

|

|

1/4

|

-4

|

1/4 - 19

|

33/64

|

0.52

|

15/32

|

0.47

|

|

3/8

|

-6

|

3/8 - 19

|

21/32

|

0.65

|

19/32

|

0.60

|

|

1/2

|

-8

|

1/2 - 14

|

13/16

|

0.82

|

3/4

|

0.75

|

|

5/8

|

-10

|

5/8 - 14

|

7/8

|

0.88

|

13/16

|

0.80

|

|

3/4

|

-12

|

3/4 - 14

|

1

1/32

|

1.04

|

31/32

|

0.97

|

|

1

|

-16

|

1 - 11

|

1

5/16

|

1.30

|

1

7/32

|

1.22

|

|

1

1/4

|

-20

|

1

1/4 - 11

|

1

21/32

|

1.65

|

1

9/16

|

1.56

|

|

1

1/2

|

-24

|

1

1/2 - 11

|

1

7/8

|

1.88

|

1

25/32

|

1.79

|

|

2

|

-32

|

2 - 11

|

2

11/32

|

2.35

|

2

1/4

|

2.26

|

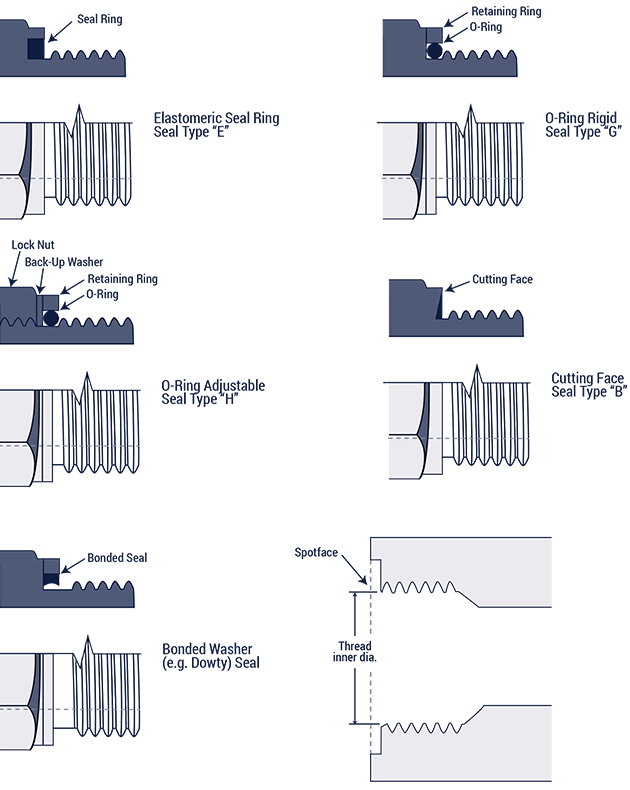

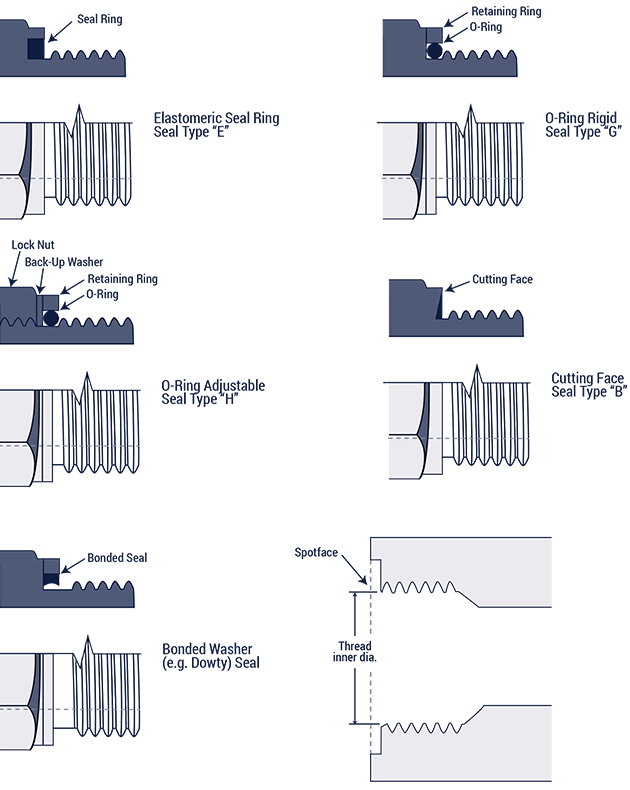

Flat Face Port with British Standard Pipe Parallel Threads (ISO 1179-1) :

DIN 3852, Part 2

These connectors form their seal between the male half and the smooth surface of the female half, using a combination of rings or washers between their parallel threads.

Flat Face Port with Metric Threads (ISO 9974-1) :

DIN 3852, Part 1

These connectors form their seal between the male half and the smooth surface of the female half, using a combination of rings or washers between their parallel threads.

ISO 261 Metric threads

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

M8 x 1.0

|

8

|

7

|

|

M10 x 1.0

|

10

|

9

|

|

M12 x 1.5

|

12

|

10.5

|

|

M14 x 1.5

|

14

|

12.5

|

|

M16 x 1.5

|

16

|

14.5

|

|

M18 x 1.5

|

18

|

16.5

|

|

M20 x 1.5

|

20

|

18.5

|

|

M22 x 1.5

|

22

|

20.5

|

|

M24 x 1.5

|

24

|

22.5

|

|

M26 x 1.5

|

26

|

24.5

|

|

M27 x 2.0

|

27

|

25

|

|

M33 x 2.0

|

33

|

31

|

|

M36 x 2.0

|

36

|

34

|

|

M42 x 2.0

|

42

|

40

|

|

M45 x 2.0

|

45

|

43

|

|

M48 x 2.0

|

48

|

46

|

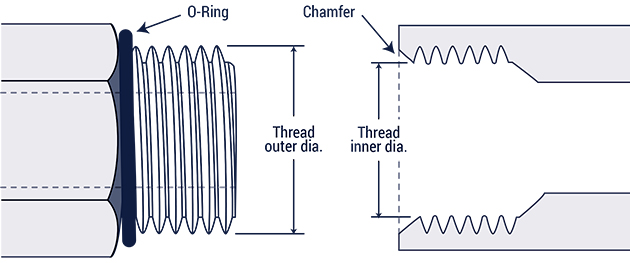

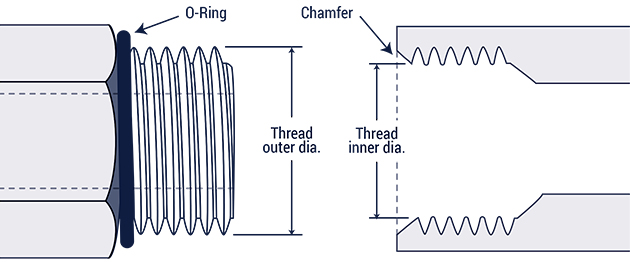

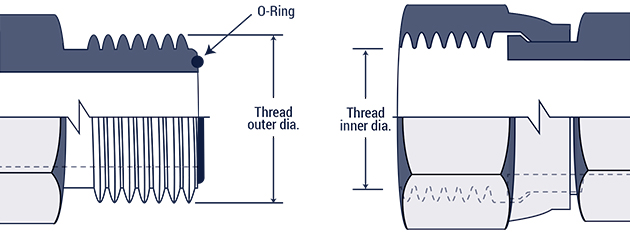

ISO 6149 Metric Port and Stud Ends :

ISO 261 threads & O-ring seal

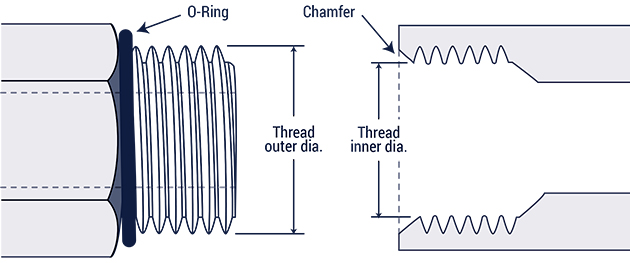

Connection with both male and female halves having straight threads. The female half has a smooth surface and a chamfer, and the male half has an O-ring. That O-ring compresses against the female chamfer to form the seal. . The male and female threads mesh to form a solid connection.

NOTE: Except for the metric threads on the ISO 6149, it connects in the same way as the SAE J1926-1O-ring Boss.

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

M8 x 1.0

|

8

|

7

|

|

M10 x 1.0

|

10

|

9

|

|

M12 x 1.5

|

12

|

10.5

|

|

M14 x 1.5

|

14

|

12.5

|

|

M16 x 1.5

|

16

|

14.5

|

|

M18 x 1.5

|

18

|

16.5

|

|

M22 x 1.5

|

22

|

20.5

|

|

M27 x 2.0

|

27

|

25

|

|

M33 x 2.0

|

33

|

31

|

|

M42 x 2.0

|

42

|

40

|

|

M48 x 2.0

|

48

|

46

|

|

M60 x 2.0

|

60

|

58

|

Metric 60° Cone :

DIN 7631

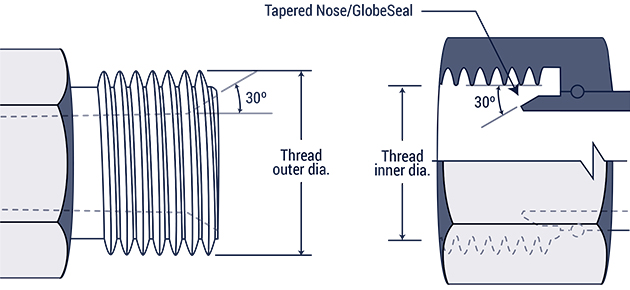

These connectors commonly found in hydraulic systems. The female connector has a globeseal seat, while the male has a 60° recessed cone (which forms the seal against the female's tapered nose). Both male and female have straight threads, that mesh to form a solid connection.

|

Pipe/Tube O.D. (mm)

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

6

|

M12 x 1.5

|

12

|

10.5

|

|

8

|

M14 x 1.5

|

14

|

12.5

|

|

10

|

M16 x 1.5

|

16

|

14.5

|

|

12

|

M18 x 1.5

|

18

|

16.5

|

|

15

|

M22 x 1.5

|

22

|

20.5

|

|

18

|

M26 x 1.5

|

26

|

24.5

|

|

22

|

M30 x 1.5

|

30

|

28.5

|

|

28

|

M38 x 1.5

|

38

|

36.5

|

|

35

|

M45 x 1.5

|

45

|

43.5

|

|

52

|

M52 x 1.5

|

52

|

50.5

|

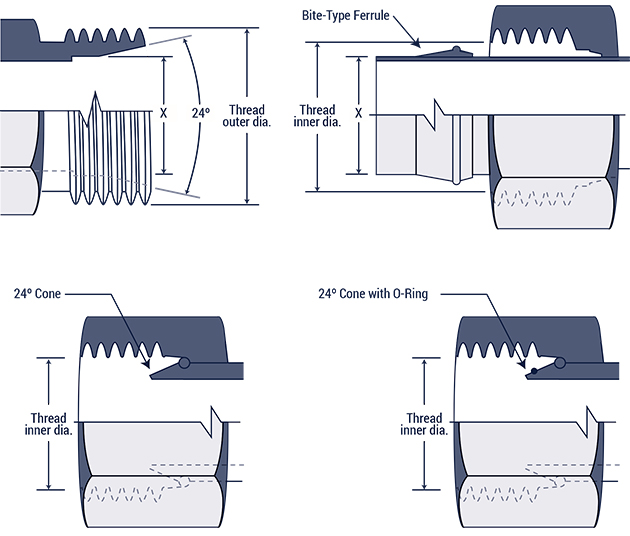

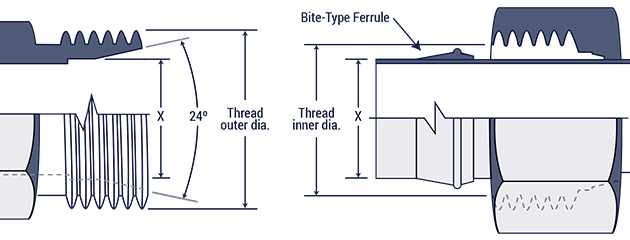

Metric Compression Fittings (DIN 2353 24° Cone) :

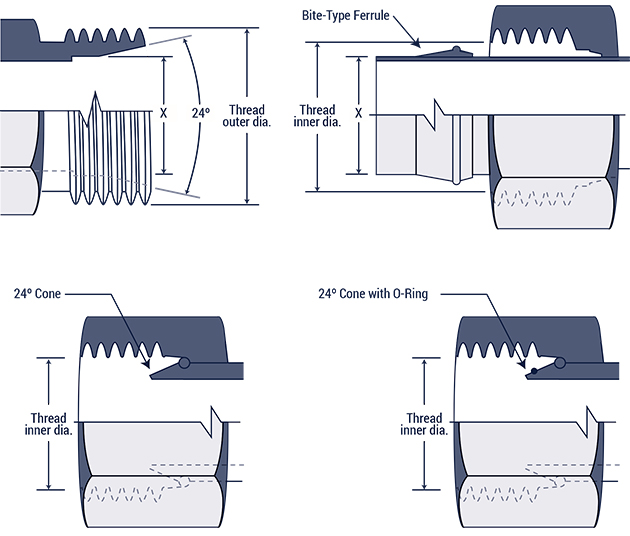

Both male and female connectors have straight threads, with the male having a 240 cone, and the three female connectors a sealing surface. The 240 cone (male) and the sealing surfaces (females) form the seal.

There are two types of connectors - the DIN 2353 L light class, and the DIN 2353 S heavy class. The chart below lists tube sizes and thread dimensions for each class:

|

DIN 2353 L Tube O.D.(mm)

|

DIN 2353 S Tube O.D. (mm)

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

6

|

|

M12 x 1.5

|

12

|

10.5

|

|

8

|

6

|

M14 x 1.5

|

14

|

12.5

|

|

10

|

8

|

M16 x 1.5

|

16

|

14.5

|

|

12

|

10

|

M18 x 1.5

|

18

|

16.5

|

|

|

12

|

M20 x 1.5

|

20

|

18.5

|

|

15

|

14

|

M22 x 1.5

|

22

|

20.5

|

|

|

16

|

M24 x 1.5

|

24

|

22.5

|

|

18

|

|

M26 x 1.5

|

26

|

24.5

|

|

22

|

20

|

M30 x 2.0

|

30

|

28

|

|

28

|

25

|

M36 x 2.0

|

36

|

34

|

|

|

30

|

M42 x 2.0

|

42

|

40

|

|

35

|

|

M45 x 2.0

|

45

|

43

|

|

42

|

38

|

M52 x 2.0

|

52

|

50

|

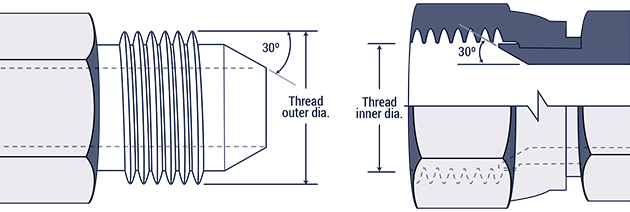

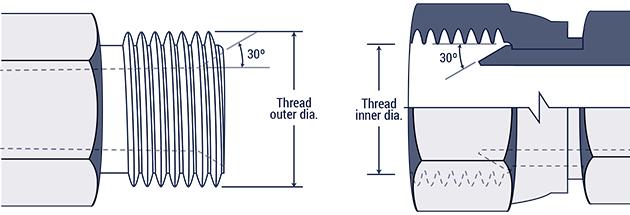

Japanese Industrial Standard JIS 300 Flare :

Both male and female connectors have straight threads, however the female has a 300 seat, and the male a 30° seat. (Although the 30° seat and BSPP-like thread dimensions differ from the American 37° Flare, the connections are very much alike.)

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

1/8 - 28

|

3/8

|

0.38

|

11/32

|

0.35

|

|

1/4

|

-4

|

1/4 - 19

|

33/64

|

0.52

|

15/32

|

0.47

|

|

3/8

|

-6

|

3/8 - 19

|

21/32

|

0.65

|

19/32

|

0.60

|

|

1/2

|

-8

|

1/2 - 14

|

13/16

|

0.82

|

3/4

|

0.75

|

|

5/8

|

-10

|

5/8 - 14

|

7/8

|

0.88

|

13/16

|

0.80

|

|

3/4

|

-12

|

3/4 - 14

|

1

1/32

|

1.04

|

31/32

|

0.97

|

|

1

|

-16

|

1 - 11

|

1

5/16

|

1.30

|

1

7/32

|

1.22

|

|

1

1/4

|

-20

|

1

1/4 - 11

|

1

21/32

|

1.65

|

1

9/16

|

1.56

|

|

1

1/2

|

-24

|

1

1/2 - 11

|

1

7/8

|

1.88

|

1

25/32

|

1.79

|

|

2

|

-32

|

2 - 11

|

2

11/32

|

2.35

|

2

1/4

|

2.26

|

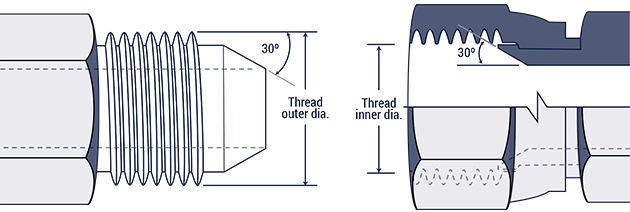

Komatsu 30° Flare (JIS Metric) :

These connectors are commonly used on Komatsu equipment. With a 30° seat and parallel metric threads, it's not unlike the JIS 300 flare (the difference being the metric threads vs. the BSPP-like thread dimensions on the JIS 300).

|

Dash Size

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

-6

|

M18 x 1.5

|

18

|

16.5

|

|

-8

|

M22 x 1.5

|

22

|

20.5

|

|

-10

|

M24 x 1.5

|

24

|

22.5

|

|

-12

|

M30 x 1.5

|

30

|

28.5

|

|

-16

|

M33 x 1.5

|

33

|

31.5

|

|

-20

|

M36 x 1.5

|

36

|

34.5

|

|

-24

|

M42 x 1.5

|

42

|

40.5

|

|

Inch size

|

Dash size

|

Threads per Inch

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

27

|

13/32

|

0.41

|

3/8

|

0.38

|

|

1/4

|

-4

|

18

|

17/32

|

0.54

|

1/2

|

0.49

|

|

3/8

|

-6

|

14

|

11/16

|

0.68

|

5/8

|

0.63

|

|

1/2

|

-8

|

14

|

27/32

|

0.84

|

25/32

|

0.77

|

|

3/4

|

-12

|

14

|

1

1/16

|

1.05

|

1

|

0.98

|

|

1

|

-16

|

11

1/2

|

1

5/16

|

1.32

|

1

1/4

|

1.24

|

|

1

1/4

|

-20

|

11

1/2

|

1

21/32

|

1.66

|

1

19/32

|

1.58

|

|

1

1/2

|

-24

|

11

1/2

|

1

29/32

|

1.90

|

1

13/16

|

1.82

|

|

2

|

-32

|

11

1/2

|

2

3/8

|

2.38

|

2

5/16

|

2.30

|

National Pipe Straight Mechanical (NPSM) :

A connection where the male thread (with a 300 internal chamfer), and female thread (with an inverted 300 seat), are both straight. When the two are threaded together, the tapered seat forms a leak-resistant connection. These connections are used widely across fluid power systems.

NOTE: A NPSM female and a chamfered NPTF male can form a seal together.

|

Inch size

|

Dash size

|

Threads per Inch

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

27

|

13/32

|

0.41

|

3/8

|

0.38

|

|

1/4

|

-4

|

18

|

17/32

|

0.54

|

1/2

|

0.49

|

|

3/8

|

-6

|

14

|

11/16

|

0.68

|

5/8

|

0.63

|

|

1/2

|

-8

|

14

|

27/32

|

0.84

|

25/32

|

0.77

|

|

3/4

|

-12

|

14

|

1

1/16

|

1.05

|

1

|

0.98

|

|

1

|

-16

|

11

1/2

|

1

5/16

|

1.32

|

1

1/4

|

1.24

|

|

1

1/4

|

-20

|

11

1/2

|

1

21/32

|

1.66

|

1

19/32

|

1.58

|

|

1

1/2

|

-24

|

11

1/2

|

1

29/32

|

1.90

|

1

13/16

|

1.82

|

|

2

|

-32

|

11

1/2

|

2

3/8

|

2.38

|

2

5/16

|

2.30

|

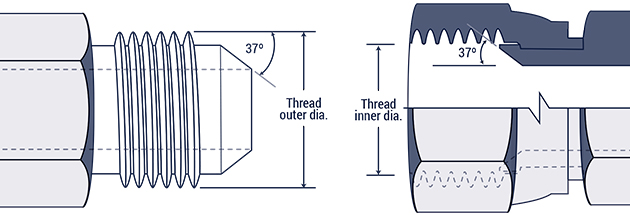

JIC 37° Flare (SAE J514) :

This connection is widely used in hydraulic systems, and both the male and female connectors have straight threads and a 37º flare seat. The straight threads of each half hold the connection together, sealing the flared seats.

NOTE: Most SAE J514 threads are exactly the same as the SAE 45º flare threads, however their seating angles differ.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

5/16 - 24

|

5/16

|

0.31

|

9/32

|

0.27

|

|

3/16

|

-3

|

3/8 - 24

|

3/8

|

0.38

|

11/32

|

0.34

|

|

1/4

|

-4

|

7/16 - 20

|

7/16

|

0.44

|

13/32

|

0.39

|

|

5/16

|

-5

|

1/2 - 20

|

1/2

|

0.50

|

15/32

|

0.45

|

|

3/8

|

-6

|

9/16 - 18

|

9/16

|

0.56

|

17/32

|

0.51

|

|

1/2

|

-8

|

3/4 - 16

|

3/4

|

0.75

|

11/16

|

0.69

|

|

5/8

|

-10

|

7/8 - 14

|

7/8

|

0.88

|

13/16

|

0.81

|

|

3/4

|

-12

|

1

1/16 - 12

|

11/16

|

1.06

|

1

|

0.98

|

|

7/8

|

-14

|

1

3/16 - 12

|

1

3/16

|

1.19

|

1

1/8

|

1.10

|

|

1

|

-16

|

1

5/16-12

|

1

5/16

|

1.31

|

1

1/4

|

1.23

|

|

1

1/4

|

-20

|

1

5/8 - 12

|

1

5/8

|

1.63

|

1

9/16

|

1.54

|

|

1

1/2

|

-24

|

1

7/8 - 12

|

1

7/8

|

1.88

|

1

13/16

|

1.79

|

|

2

|

-32

|

2

1/2 - 12

|

2

1/2

|

2.50

|

2

7/16

|

2.42

|

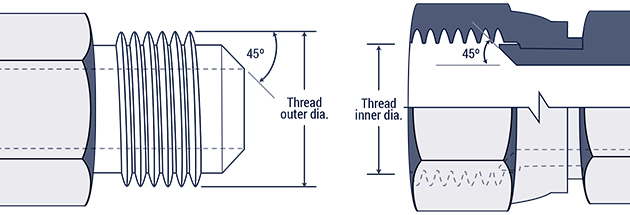

SAE 45° Flare (SAE J512) :

Typically used with low pressure systems like refrigerant lines, fuel lines, and automotive applications, the SAE male and female connectors similarly have a 45° flare seat which forms the seal. The threads of both halves mesh together for a strong mechanical connection. The SAE 45° Flare connectors are exactly the same as the JIC 37° Flare connectors, however their seating angles differ.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

5/16 - 24

|

5/16

|

0.31

|

9/32

|

0.27

|

|

3/16

|

-3

|

3/8 - 24

|

3/8

|

0.38

|

11/32

|

0.34

|

|

1/4

|

-4

|

7/16 - 20

|

7/16

|

0.44

|

13/32

|

0.39

|

|

5/16

|

-5

|

1/2 - 20

|

1/2

|

0.50

|

15/32

|

0.45

|

|

3/8

|

-6

|

5/8 - 18

|

5/8

|

0.63

|

9/16

|

0.57

|

|

1/2

|

-8

|

3/4 - 16

|

3/4

|

0.75

|

11/16

|

0.69

|

|

5/8

|

-10

|

7/8 - 14

|

7/8

|

0.88

|

13/16

|

0.81

|

|

3/4

|

-12

|

1

1/16 - 14

|

11/16

|

1.06

|

1

|

0.99

|

|

7/8

|

-14

|

1

1/4 - 12

|

1

1/4

|

1.25

|

1

5/32

|

1.16

|

|

1

|

-16

|

1

3/8 - 12

|

1

3/8

|

1.38

|

1

9/32

|

1.29

|

SAE Straight Thread O-ring (O-Ring Boss) :

SAE J1926-1 and ISO 11296-1

A connection commonly found in high pressure hydraulic systems. While both halves have straight threads, the female has a sealing face and chamfer, and the male has an O-ring which when compressed into the opposing chamfer, forms the seal. The male and female threads mesh to form a solid connection.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

5/16 - 24

|

5/16

|

0.31

|

9/32

|

0.27

|

|

3/16

|

-3

|

3/8 - 24

|

3/8

|

0.38

|

11/32

|

0.34

|

|

1/4

|

-4

|

7/16 - 20

|

7/16

|

0.44

|

13/32

|

0.39

|

|

5/16

|

-5

|

1/2 - 20

|

1/2

|

0.50

|

15/32

|

0.45

|

|

3/8

|

-6

|

9/16 - 18

|

9/16

|

0.56

|

17/32

|

0.51

|

|

1/2

|

-8

|

3/4 - 16

|

3/4

|

0.75

|

11/16

|

0.69

|

|

5/8

|

-10

|

7/8 - 14

|

7/8

|

0.88

|

13/16

|

0.81

|

|

3/4

|

-12

|

1

1/16 - 12

|

11/16

|

1.06

|

1

|

0.98

|

|

7/8

|

-14

|

1

3/16 - 12

|

1

3/16

|

1.19

|

1

1/8

|

1.10

|

|

1

|

-16

|

1

5/16 - 12

|

1

5/16

|

1.31

|

1

1/4

|

1.23

|

|

1

1/4

|

-20

|

1

5/8 - 12

|

1

5/8

|

1.63

|

1

9/16

|

1.54

|

|

1

1/2

|

-24

|

1

7/8 - 12

|

1

7/8

|

1.88

|

1

13/16

|

1.79

|

|

2

|

-32

|

2

1/2 - 12

|

2

1/2

|

2.50

|

2

7/16

|

2.42

|

Compression Tube Fittings (SAE J514) :

The female connector includes a compression sleeve, a female nut, and a tube. The male connector has a 240 seat, which makes the seal with the female compression sleeve (the seal forms on the female side between the tubing and the compression sleeve). With non-flared tube fittings with straight threads, the male and female threads mesh to form a solid connection.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

5/16 - 24

|

5/16

|

0.31

|

9/32

|

0.27

|

|

3/16

|

-3

|

3/8 - 24

|

3/8

|

0.38

|

11/32

|

0.34

|

|

1/4

|

-4

|

7/16 - 20

|

7/16

|

0.44

|

13/32

|

0.39

|

|

5/16

|

-5

|

1/2 - 20

|

1/2

|

0.50

|

15/32

|

0.45

|

|

3/8

|

-6

|

9/16 - 18

|

9/16

|

0.56

|

17/32

|

0.51

|

|

1/2

|

-8

|

3/4 - 16

|

3/4

|

0.75

|

11/16

|

0.69

|

|

5/8

|

-10

|

7/8 - 14

|

7/8

|

0.88

|

13/16

|

0.81

|

|

3/4

|

-12

|

1

1/16 - 12

|

11/16

|

1.06

|

1

|

0.98

|

|

7/8

|

-14

|

1

3/16 - 12

|

1

3/16

|

1.19

|

1

1/8

|

1.10

|

|

1

|

-16

|

1

5/16 - 12

|

1

5/16

|

1.31

|

1

1/4

|

1.23

|

|

1

1/4

|

-20

|

1

5/8 - 12

|

1

5/8

|

1.63

|

1

9/16

|

1.54

|

|

1

1/2

|

-24

|

1

7/8 - 12

|

1

7/8

|

1.88

|

1

13/16

|

1.79

|

|

2

|

-32

|

2

1/2 - 12

|

2

1/2

|

2.50

|

2

7/16

|

2.42

|

O-Ring Face Seal (SAE J1453) :

These fittings join to form a highly leak resistive connection, in applications up to 6000 psi. Both halves have a straight thread, with the female having a flat surface and the male connector containing an O-ring. The seal is made when the O-ring on the male compresses against the flat surface of the female. The outside nut on the female connector holds the connection together.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/4

|

-4

|

9/16 - 18

|

9/16

|

0.56

|

17/32

|

0.51

|

|

3/8

|

-6

|

11/16 - 16

|

11/16

|

0.69

|

5/8

|

0.63

|

|

1/2

|

-8

|

13/16 - 16

|

13/16

|

0.82

|

3/4

|

0.75

|

|

5/8

|

-10

|

1 - 14

|

1

|

1.00

|

15/16

|

0.93

|

|

3/4

|

-12

|

1

3/16 - 12

|

13/16

|

1.19

|

1

1/8

|

1.11

|

|

1

|

-16

|

1

7/16 - 12

|

1

7/16

|

1.44

|

1

3/4

|

1.36

|

|

1

1/4

|

-20

|

1

11/16 - 12

|

1

11/16

|

1.69

|

1

5/8

|

1.61

|

|

1

1/2

|

-24

|

2-12

|

2

|

2.00

|

1

15/16

|

1.92

|

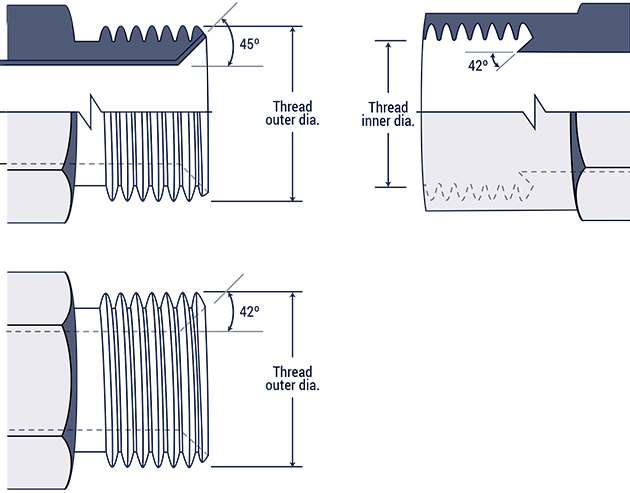

SAE Inverted Flare (SAE J512) :

These connectors are widely used in the automotive industry. With the flared male tubing having a 450 seat, and the machined connector a 420 seat, the sealing surface is formed with the 420 seat on the end of the flare of the female connector. The male and female threads mesh to form a solid connection.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

5/16 - 28

|

5/16

|

0.31

|

9/32

|

0.27

|

|

3/16

|

-3

|

3/8 - 24

|

3/8

|

0.38

|

11/32

|

0.34

|

|

1/4

|

-4

|

7/16 - 24

|

7/16

|

0.44

|

13/32

|

0.39

|

|

5/16

|

-5

|

1/2 - 20

|

1/2

|

0.50

|

15/32

|

0.45

|

|

3/8

|

-6

|

5/8 - 18

|

5/8

|

0.63

|

9/16

|

0.57

|

|

7/16

|

-7

|

11/16 - 18

|

11/16

|

0.69

|

5/8

|

0.63

|

|

1/2

|

-8

|

3/4 - 18

|

3/4

|

0.75

|

23/32

|

0.70

|

|

5/8

|

-10

|

7/8 - 18

|

7/8

|

0.88

|

13/16

|

0.81

|

|

3/4

|

-12

|

1

1/16 - 16

|

1

1/16

|

1.06

|

1

|

1.00

|

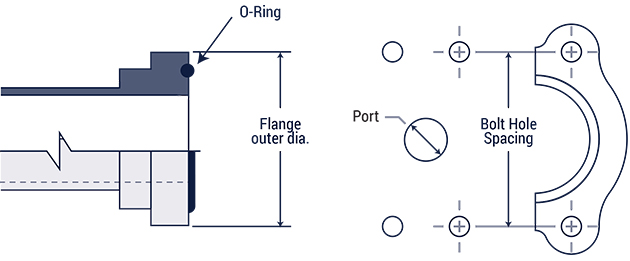

Four-Bolt Flange (SAE J518 and ISO 6162) :

These commonly used in fluid power systems, and suitable for joining 1/2" - 3" hose or tube. The seal forms between the flat surface of the female port and the O-ring of the male (seated in the ring groove). A split clamp, using 4 bolts, hold the male/female together.

Note that there are two types of SAE J518 flanges available: standard pressure (code 61), and high pressure (code 62).

|

Inch size

|

Dash size

|

Code 61 Bolt Spacing

|

Code 61 Flange O.D.

|

Code 62 Bolt Spacing

|

Code 62 Flange O.D.

|

|

1/2

|

-8

|

1

1/2

|

1

3/16

|

1

19/32

|

1

1/4

|

|

3/4

|

-12

|

1

7/8

|

1

1/2

|

2

|

1

5/8

|

|

1

|

-16

|

2

1/16

|

1

3/4

|

2

1/4

|

1

7/8

|

|

1

1/4

|

-20

|

2

5/16

|

2

|

2

5/8

|

2

1/8

|

|

1

1/2

|

-24

|

2

3/4

|

2

3/8

|

3

1/8

|

2

1/2

|

|

2

|

-32

|

3

1/16

|

2

13/32

|

3

13/16

|

3

1/8

|

|

2

1/2

|

-40

|

3

1/2

|

3

5/16

|

n/a

|

n/a

|

|

3

|

-48

|

4

3/16

|

4

|

n/a

|

n/a

|

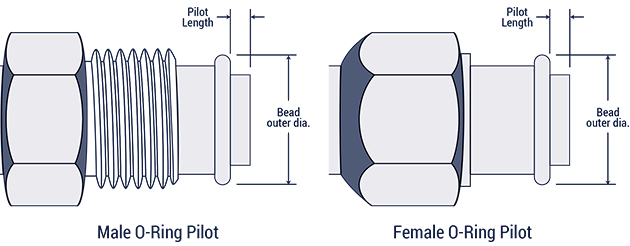

O-Ring Pilot Threads :

These connections are typically seen in automotive and commercial air conditioning applications. Both halves of the connection have a pilot, making the seal by compressing the O-ring. The male and female threads mesh to form a solid connection.

|

Inch size

|

Dash size

|

Male Thread

|

Female thread

|

|

Thread size

|

Thread O.D.

|

Thread size

|

Thread I.D.

|

|

3/8

|

-6

|

5/8 - 18

|

5/8

|

5/8 - 18

|

9/16

|

|

1/2

|

-8

|

3/4 - 18

|

3/4

|

3/4 - 16

|

11/16

|

|

5/8

|

-10

|

7/8 - 18

|

7/8

|

7/8 - 14

|

13/16

|

|

3/4

|

-12

|

1

1/16 - 16

|

1

1/16

|

1

1/16 - 14

|

1

|

|

Inch size

|

Dash size

|

Long pilot

|

Short pilot

|

|

Bead O.D. (in)

|

Pilot Length (in)

|

Bead O.D. (in)

|

Pilot Length (in)

|

|

3/8

|

-6

|

0.52

|

0.28

|

0.52

|

0.19

|

|

1/2

|

-8

|

0.64

|

0.39

|

0.64

|

0.19

|

|

5/8

|

-10

|

0.77

|

0.39

|

0.77

|

0.19

|

|

3/4

|

-12

|

0.91

|

0.39

|

0.91

|

0.19

|

INTERNATIONAL CONNECTIONS

British Standard Pipe

British Standard Pipe connections come in two different types: British Standard Pipe Parallel (BSPP); and British Standard Pipe Tapered (BSPT).

British Standard Pipe Parallel (BSPP) :

This connection has a male half with a 300 seat, and a female half with a rotating tapered nose, that forms the seal.

NOTE: The male connector may appear to look like the male American National Pipe Straight Mechanical, or NPSM; however, their thread pitches are not the same, and are not compatible.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

1/8 - 28

|

3/8

|

0.38

|

11/32

|

0.35

|

|

1/4

|

-4

|

1/4 - 19

|

33/64

|

0.52

|

15/32

|

0.47

|

|

3/8

|

-6

|

3/8 - 19

|

21/32

|

0.65

|

19/32

|

0.60

|

|

1/2

|

-8

|

1/2 - 14

|

13/16

|

0.82

|

3/4

|

0.75

|

|

5/8

|

-10

|

5/8 - 14

|

7/8

|

0.88

|

13/16

|

0.80

|

|

3/4

|

-12

|

3/4 - 14

|

1

1/32

|

1.04

|

31/32

|

0.97

|

|

1

|

-16

|

1 - 11

|

1

5/16

|

1.30

|

1

7/32

|

1.22

|

|

1

1/4

|

-20

|

1

1/4 - 11

|

1

21/32

|

1.65

|

1

9/16

|

1.56

|

|

1

1/2

|

-24

|

1

1/2 - 11

|

1

7/8

|

1.88

|

1

25/32

|

1.79

|

|

2

|

-32

|

2 - 11

|

2

11/32

|

2.35

|

2

1/4

|

2.26

|

British Standard Pipe Tapered (BSPT) :

These are connectors where the seal is made between a tapered male and female thread.

NOTE: Although the BSPT male connector appears to look like the National Pipe Tapered Fuel, or NPTF; their thread size and form are not the same and therefore they are not compatible.

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

1/8 - 28

|

3/8

|

0.38

|

11/32

|

0.35

|

|

1/4

|

-4

|

1/4 - 19

|

33/64

|

0.52

|

15/32

|

0.47

|

|

3/8

|

-6

|

3/8 - 19

|

21/32

|

0.65

|

19/32

|

0.60

|

|

1/2

|

-8

|

1/2 - 14

|

13/16

|

0.82

|

3/4

|

0.75

|

|

5/8

|

-10

|

5/8 - 14

|

7/8

|

0.88

|

13/16

|

0.80

|

|

3/4

|

-12

|

3/4 - 14

|

1

1/32

|

1.04

|

31/32

|

0.97

|

|

1

|

-16

|

1 - 11

|

1

5/16

|

1.30

|

1

7/32

|

1.22

|

|

1

1/4

|

-20

|

1

1/4 - 11

|

1

21/32

|

1.65

|

1

9/16

|

1.56

|

|

1

1/2

|

-24

|

1

1/2 - 11

|

1

7/8

|

1.88

|

1

25/32

|

1.79

|

|

2

|

-32

|

2 - 11

|

2

11/32

|

2.35

|

2

1/4

|

2.26

|

Flat Face Port with British Standard Pipe Parallel Threads (ISO 1179-1) :

DIN 3852, Part 2

These connectors form their seal between the male half and the smooth surface of the female half, using a combination of rings or washers between their parallel threads.

Flat Face Port with Metric Threads (ISO 9974-1) :

DIN 3852, Part 1

These connectors form their seal between the male half and the smooth surface of the female half, using a combination of rings or washers between their parallel threads.

ISO 261 Metric threads

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

M8 x 1.0

|

8

|

7

|

|

M10 x 1.0

|

10

|

9

|

|

M12 x 1.5

|

12

|

10.5

|

|

M14 x 1.5

|

14

|

12.5

|

|

M16 x 1.5

|

16

|

14.5

|

|

M18 x 1.5

|

18

|

16.5

|

|

M20 x 1.5

|

20

|

18.5

|

|

M22 x 1.5

|

22

|

20.5

|

|

M24 x 1.5

|

24

|

22.5

|

|

M26 x 1.5

|

26

|

24.5

|

|

M27 x 2.0

|

27

|

25

|

|

M33 x 2.0

|

33

|

31

|

|

M36 x 2.0

|

36

|

34

|

|

M42 x 2.0

|

42

|

40

|

|

M45 x 2.0

|

45

|

43

|

|

M48 x 2.0

|

48

|

46

|

ISO 6149 Metric Port and Stud Ends :

ISO 261 threads & O-ring seal

Connection with both male and female halves having straight threads. The female half has a smooth surface and a chamfer, and the male half has an O-ring. That O-ring compresses against the female chamfer to form the seal. . The male and female threads mesh to form a solid connection.

NOTE: Except for the metric threads on the ISO 6149, it connects in the same way as the SAE J1926-1O-ring Boss.

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

M8 x 1.0

|

8

|

7

|

|

M10 x 1.0

|

10

|

9

|

|

M12 x 1.5

|

12

|

10.5

|

|

M14 x 1.5

|

14

|

12.5

|

|

M16 x 1.5

|

16

|

14.5

|

|

M18 x 1.5

|

18

|

16.5

|

|

M22 x 1.5

|

22

|

20.5

|

|

M27 x 2.0

|

27

|

25

|

|

M33 x 2.0

|

33

|

31

|

|

M42 x 2.0

|

42

|

40

|

|

M48 x 2.0

|

48

|

46

|

|

M60 x 2.0

|

60

|

58

|

Metric 60° Cone :

DIN 7631

These connectors commonly found in hydraulic systems. The female connector has a globeseal seat, while the male has a 60° recessed cone (which forms the seal against the female's tapered nose). Both male and female have straight threads, that mesh to form a solid connection.

|

Pipe/Tube O.D. (mm)

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

6

|

M12 x 1.5

|

12

|

10.5

|

|

8

|

M14 x 1.5

|

14

|

12.5

|

|

10

|

M16 x 1.5

|

16

|

14.5

|

|

12

|

M18 x 1.5

|

18

|

16.5

|

|

15

|

M22 x 1.5

|

22

|

20.5

|

|

18

|

M26 x 1.5

|

26

|

24.5

|

|

22

|

M30 x 1.5

|

30

|

28.5

|

|

28

|

M38 x 1.5

|

38

|

36.5

|

|

35

|

M45 x 1.5

|

45

|

43.5

|

|

52

|

M52 x 1.5

|

52

|

50.5

|

Metric Compression Fittings (DIN 2353 24° Cone) :

Both male and female connectors have straight threads, with the male having a 240 cone, and the three female connectors a sealing surface. The 240 cone (male) and the sealing surfaces (females) form the seal.

There are two types of connectors - the DIN 2353 L light class, and the DIN 2353 S heavy class. The chart below lists tube sizes and thread dimensions for each class:

|

DIN 2353 L Tube O.D.(mm)

|

DIN 2353 S Tube O.D. (mm)

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

6

|

|

M12 x 1.5

|

12

|

10.5

|

|

8

|

6

|

M14 x 1.5

|

14

|

12.5

|

|

10

|

8

|

M16 x 1.5

|

16

|

14.5

|

|

12

|

10

|

M18 x 1.5

|

18

|

16.5

|

|

|

12

|

M20 x 1.5

|

20

|

18.5

|

|

15

|

14

|

M22 x 1.5

|

22

|

20.5

|

|

|

16

|

M24 x 1.5

|

24

|

22.5

|

|

18

|

|

M26 x 1.5

|

26

|

24.5

|

|

22

|

20

|

M30 x 2.0

|

30

|

28

|

|

28

|

25

|

M36 x 2.0

|

36

|

34

|

|

|

30

|

M42 x 2.0

|

42

|

40

|

|

35

|

|

M45 x 2.0

|

45

|

43

|

|

42

|

38

|

M52 x 2.0

|

52

|

50

|

Japanese Industrial Standard JIS 300 Flare :

Both male and female connectors have straight threads, however the female has a 300 seat, and the male a 30° seat. (Although the 30° seat and BSPP-like thread dimensions differ from the American 37° Flare, the connections are very much alike.)

|

Inch size

|

Dash size

|

Thread Size

|

Male Thread O.D. (in)

|

Female thread O.D (in)

|

|

1/8

|

-2

|

1/8 - 28

|

3/8

|

0.38

|

11/32

|

0.35

|

|

1/4

|

-4

|

1/4 - 19

|

33/64

|

0.52

|

15/32

|

0.47

|

|

3/8

|

-6

|

3/8 - 19

|

21/32

|

0.65

|

19/32

|

0.60

|

|

1/2

|

-8

|

1/2 - 14

|

13/16

|

0.82

|

3/4

|

0.75

|

|

5/8

|

-10

|

5/8 - 14

|

7/8

|

0.88

|

13/16

|

0.80

|

|

3/4

|

-12

|

3/4 - 14

|

1

1/32

|

1.04

|

31/32

|

0.97

|

|

1

|

-16

|

1 - 11

|

1

5/16

|

1.30

|

1

7/32

|

1.22

|

|

1

1/4

|

-20

|

1

1/4 - 11

|

1

21/32

|

1.65

|

1

9/16

|

1.56

|

|

1

1/2

|

-24

|

1

1/2 - 11

|

1

7/8

|

1.88

|

1

25/32

|

1.79

|

|

2

|

-32

|

2 - 11

|

2

11/32

|

2.35

|

2

1/4

|

2.26

|

Komatsu 30° Flare (JIS Metric) :

These connectors are commonly used on Komatsu equipment. With a 30° seat and parallel metric threads, it's not unlike the JIS 300 flare (the difference being the metric threads vs. the BSPP-like thread dimensions on the JIS 300).

|

Dash Size

|

Metric Thread Size

|

Male Thread O.D. (mm)

|

Female Thread I.D (mm)

|

|

-6

|

M18 x 1.5

|

18

|

16.5

|

|

-8

|

M22 x 1.5

|

22

|

20.5

|

|

-10

|

M24 x 1.5

|

24

|

22.5

|

|

-12

|

M30 x 1.5

|

30

|

28.5

|

|

-16

|

M33 x 1.5

|

33

|

31.5

|

|

-20

|

M36 x 1.5

|

36

|

34.5

|

|

-24

|

M42 x 1.5

|

42

|

40.5

|

|